Chilling a process whether medical or industrial usually requires the use of refrigerants. A refrigeration system is a closed loop circuit in which the refrigerant absorbs heat where cooling is desired (in the evaporator) and then moves the heat to some other point (the condenser) where the heat can be rejected. The refrigerant itself is recirculated over and over again.

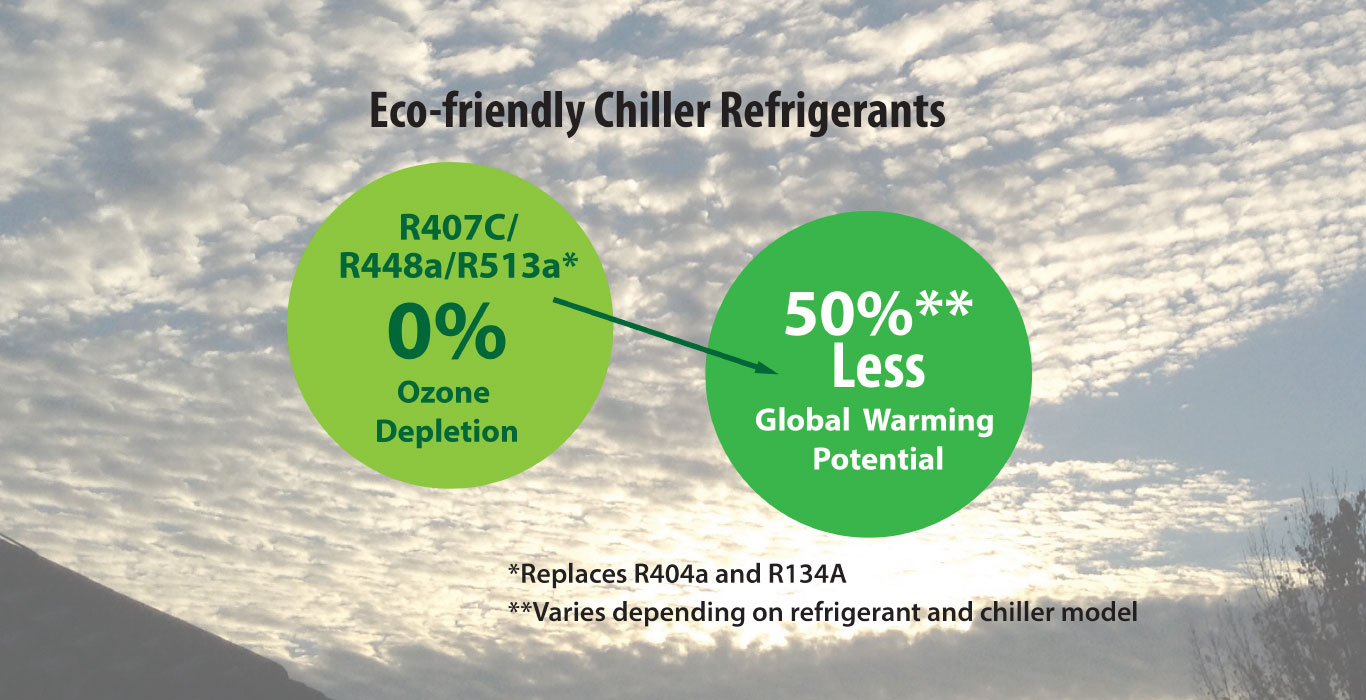

Starting with the Montreal Protocol in 1987, there is has been a push to make sure refrigerants do not harm the environment if they should leak out. The industry successfully switched to new refrigerants to stop the depletion of the earth’s ozone layer. More recently, the world is focusing on reducing the potential for adding greenhouse gases to the atmosphere. Filtrine has a history of sustainability. Using eco-friendly refrigerants in Filtrine chillers is one area that is highly effective in reducing the impact on the environment.

Depending on the application, Filtrine chillers that used R404a will now use either R407c (55% lower GWP) or R448a (67% lower GWP). Chillers that used R134a will now come with R513a which has a 55% lower GWP.

Beginning in early 2016, Filtrine began to transition towards significantly lower global warming potential (GWP) refrigerants while also increasing energy efficiency of its chillers. As it did under the Montreal Protocol to protect the earth’s ozone layer, Filtrine is quick to respond to concerns about Climate Change by using the most environment-friendly refrigerants available.

Many of Filtrine chiller models have for years been using hydrofluorocarbons (HFC) refrigerants, R404A or R134a which have zero ozone depletion potential. However, new refrigerants have recently been developed that have all of the advantages of these refrigerants but much lower GWP.

Depending on the application, Filtrine chillers that used R404a will now use either R407c (55% lower GWP) or R448a (67% lower GWP). Chillers that used R134a will now come with R513a which has a 55% lower GWP. At the same time, there is little or no loss in efficiency. In some cases, the efficiency improves by as much as 10%.

For more information on the new refrigerants, email cool@filtrine.com or contact your local Filtrine Chiller Representative.

Filtrine Featured Product

Filtrine offers the best engineering features in the business. In addition, there are more than 60 options and accessories available for all Filtrine medical, industrial process chillers or bakery chillers. You select the options to make the chiller the best fit for the site and the application. Then Filtrine will build your chiller based on your selections and requirements. For more information, visit Chiller Options & Accessories.

For more information on how to customize your chiller, contact your local Filtrine Chiller Representative today.

Don’t miss the latest “Chiller Solutions Update”. Subscribe today!