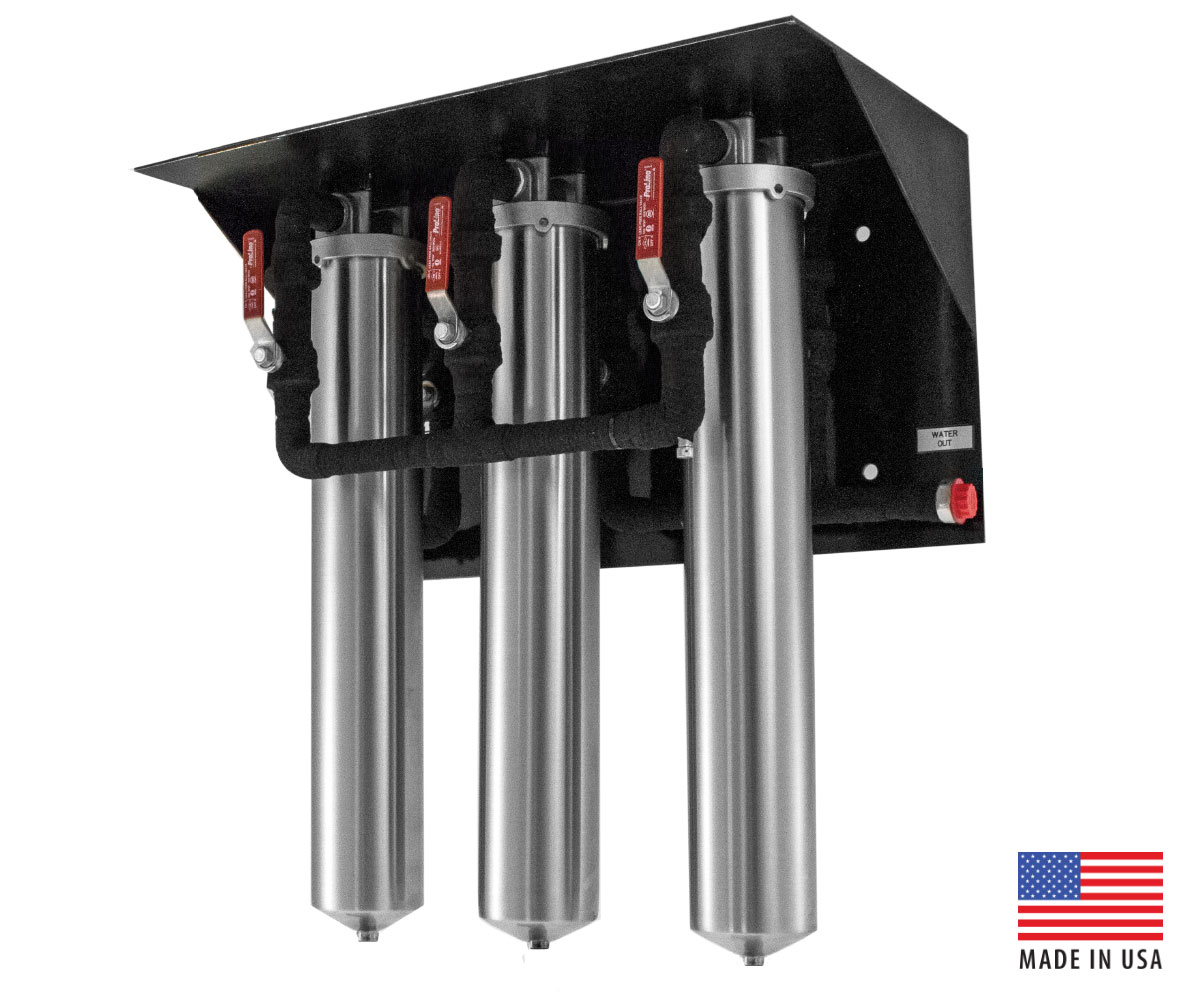

Filtrine IL5-PFSTMS-5.0 Taste Master In-line Water Purifier

Two-stage Process Removes 5 Micron Particles, Organic Tastes/Odors, Chlorine Taste/Odor; Flow Rate: 5 gpm

For applications that require serving purified water to multiple outlets in a building or an office, this two-stage purification system works by adding pre-filtration to the Taste Master water purifier using Filtrine’s particulate filter.

Low and inexpensive maintenance is one of Filtrine’s primary goals, and Filtrine guarantees that the element replacement procedure can be completed in less than 30 seconds and require no tools to perform. The environmentally friendly Filtrine filter/purifier configuration cuts down on waste, saving money over time.

Specifications:

The heavy-duty stainless steel Taste Master® in-line purifier housings are rated at 150 psi working pressure. They are built to outlast the piping in the building. The carbon block (a naturally occurring material) used in the Taste Master® purifier is biodegradable.

First Stage: The 5.0 micron spun poly filter, Filtrine’s Model PFS6-10-5-SP, removes suspended particles and increases efficiency and the life of carbon block elements.

Second Stage: The Filtrine Model TMS2-10-5-CB carbon block element meets the NSF/ANSI Standard 42 for removal of sediment down to 5 micron particles, organic tastes/odors and chlorine taste/odors.

For lead removal and a higher level of filtration, see the 0.5 micron Taste Master purifiers.

Details

Taste Master elements do not rely on cartridge compression. Filtrine’s exclusive “Dual-Seal” design ensures first-day effectiveness for the life of the element.

Flow Rate: 5 gpm

Overall Dimensions (in): 24W x 12D x 14 1/8H

Pre-Filter: Pre-Filter: [1] 16 ga. stainless steel housing [1] 5.0 micron spun poly particulate filter

Purifier: Purifier: [2] 16 ga. stainless steel housing [2] 0.5 micron Taste Master carbon block purifiers

Water Conn. (In/Out: FPT): 1/2″

Purifier Maintenance:

- Replace elements every 4 months or more often if required.

Related Applications

Industrial Water Fountains

For extreme environments such as those found at oil & gas or heavy-duty manufacturing facilities, consider the Filtrine INDESTRUCT Model IM industrial electric water coolers. In addition to saving money by eliminating bottled water shipping and storage costs, they are sustainable and durable enough for any environment. Other models include high ambient Model IM-HA, and explosion-proof Model IM-XP. For information on “Hands Free” sensor activation, contact your local Filtrine Drinking Water Representative.

Schools

School systems throughout the US have become concerned about lead in their buildings’ drinking water. Old pipes and untreated city water are the main issues. Filtrine has two ways for schools to remove lead from drinking water.

- Filtrine’s vandal proof drinking fountains, bottle filling stations and electric water coolers are popular because of their durability. Point of use drinking water chillers and purifiers can be added to drinking fountains and bottle filling stations to eliminate lead, organic tastes/odors, chlorine taste/odor and pathogens. Any Filtrine drinking fountain/bottle filling station can be made “Hands Free” to cut down on germ transmission.

- Filtrine’s point of entry water filtration system uses pre-filters, purifiers and optional UV sterilizers. It delivers lead-free water throughout the school building. Visit Point of Entry Water Filtration Explained for more information.