Filtrine Touchless Drinking Fountains in the Lab

When approaching this problem, there are many ways to tackle it, but probably the simplest is to make it easy for people to drink from a touchless fountain. For example, protecting against contamination is particularly critical in laboratories. This ensures the validity of the research and testing performed. New York State’s public health laboratory, Wadsworth Health Laboratory in Albany, who according to their website is dedicated to research “in areas such as public health genomics, microbial pathogenesis and host immunity, bacterial drug resistance, vector-borne infectious diseases, biomonitoring for environmental toxins, cellular and molecular structure analysis, adaptive neurotechnologies, and nuclear and atmospheric chemistry” decided to proactively avoid a potential breach in communal areas.

There was growing concern about lab workers becoming contaminated while drinking water from a fountain when they were doing their research. The laboratory staff were used to decontamination procedures throughout the day, but they needed a way to get water without compromising their work, or requiring yet another decontamination.

The New York Office of General Services (OGS), who oversees the facility and has been working with Filtrine since the mid-1970s, asked Filtrine to design and manufacture a drinking fountain that could be operated without the risk of cross-contamination. Filtrine designed a foot-operated sensor activated version of their fully recessed stainless steel Model 103 fountain which included an optional chiller and Taste Master® purifier. The modified version is called a “Hands Free” FCC-103-EE-MOD. The workers could drink chilled, purified water by placing their foot over an infrared sensor on the floor and avoid placing their hands anywhere near the fixture. This ultimately lowered the number of required decontaminations while hydrating the staff, saving money and time, and increasing productivity for the entire lab. The design proved to be so successful, the OGS ended up ordering eight to be installed throughout their lab.

When you need to avoid contamination when dispensing water from your drinking water fountain or water filling station, contact your local Filtrine Drinking Water Representative or fill out the Drinking Water Product Request a Quote Form for more information.

(Empire State Plaza photo courtesy of Matt Wade Photography)

Featured Filtrine Product

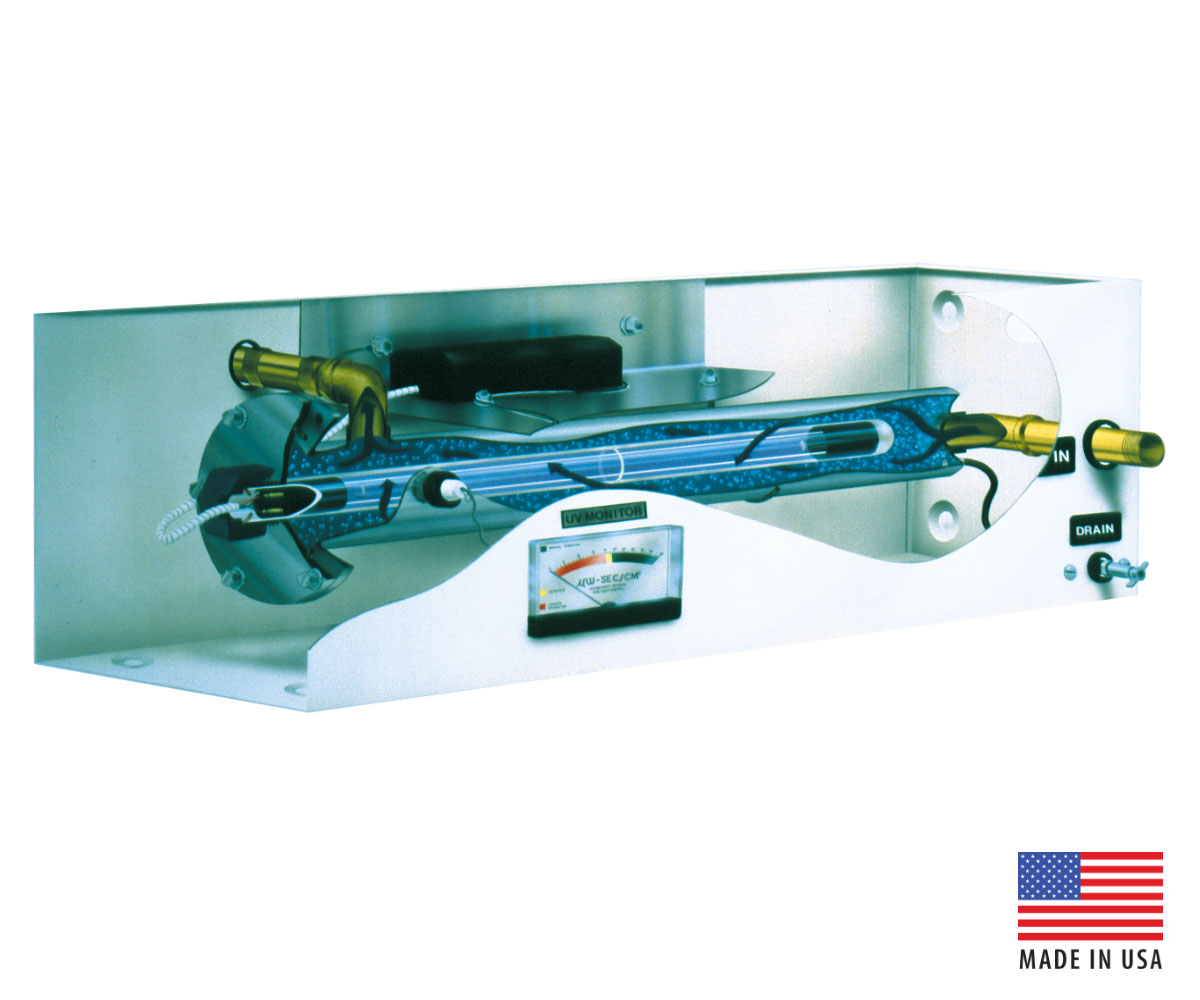

Ultraviolet (UV) water sterilization is the safe alternative to chlorine for drinking water, storage tanks or pools. It is also highly effective in rainwater recovery systems. In Filtrine’s ultraviolet sterilizers, called the Steri-Flo series, the UV radiation with a wave length of 2,536 angstrom, is produced from a low pressure mercury lamp. The lamp is encased in a special high-purity quartz sleeve, immersed in water inside of the stainless steel sterilizing chamber. By regulating the flow of water through this chamber, disease-causing micro-organisms, such as bacteria, algae, spores and viruses are exposed to a dose of at least 40,000µw-sec/cm2, over twice the dosage required to ensure safe drinking water. Specifications…

Featured INDESTRUCT Product

Filtrine’s INDESTRUCT Model IM electric water coolers are built with the most durable materials and components to withstand even the most excessive demands of heavy industry from shipyards to factories. Select from 16 ga steel panels with enamel or powder coat finish, or 16 ga stainless steel panels with satin or powder coat finish. Models also include: explosion proof, outdoor freeze proof and high ambient. Options include a push button bubbler, gooseneck bottle/glass filler, or a foot activated electronic sensor (for laboratories where cross-contamination is of the utmost importance). Learn more…

For more information on any of these models, contact your local Filtrine Drinking Water Representative today.

Don’t miss the latest “Drinking Water Solutions Update”. Subscribe today!